Reaching for the stars with a forklift truck

Sector: Specialty glass and glassceramics.

Company: 15.100 employees worldwide, 2,05 billion euro (global sales 2017), Corporate Headquarter: Mainz (Germany).

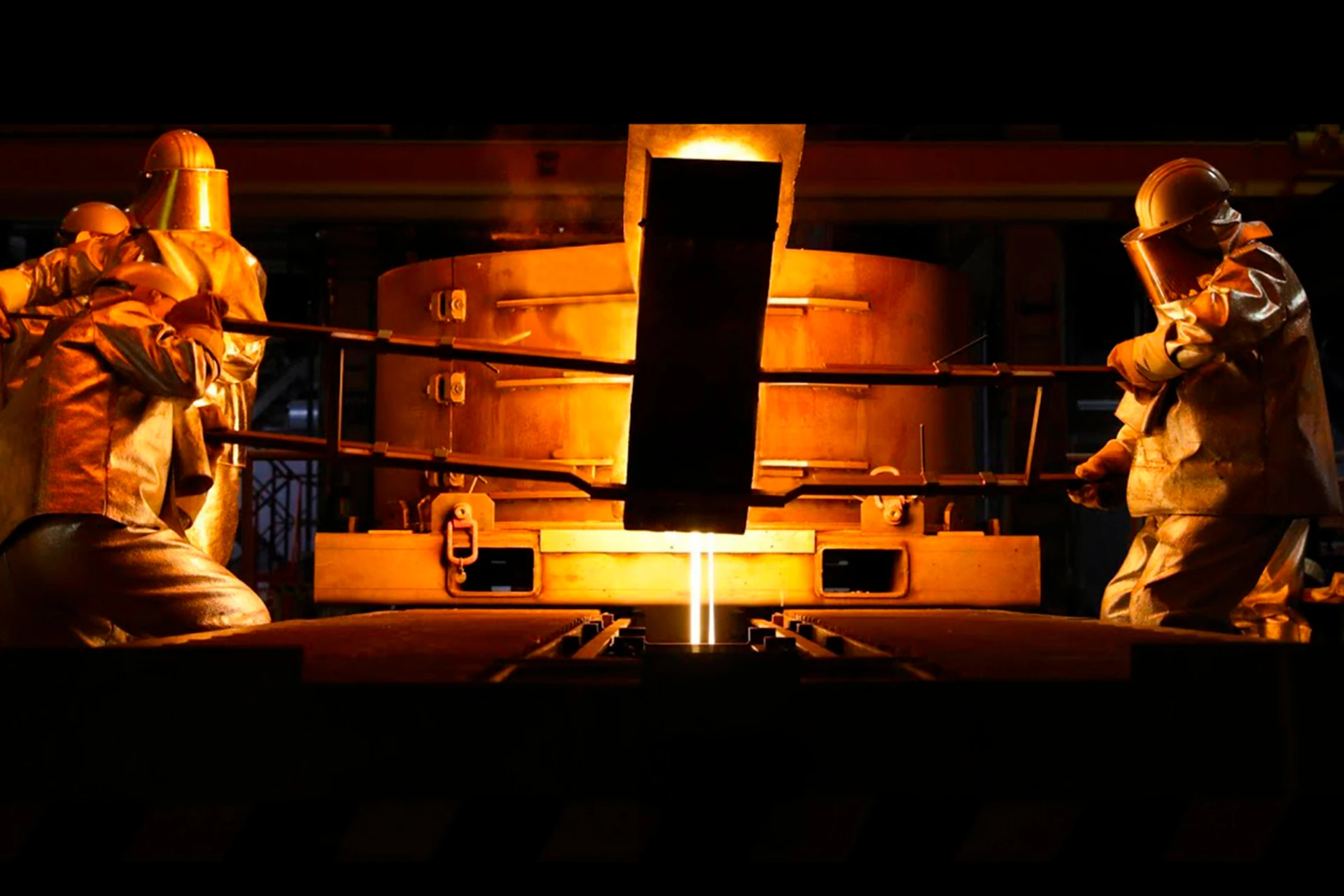

Challenge: Handling of a heavy casting mould with molten liquid glass with a diameter of up to 4,25 meters.

STILL products: STILL RX 60-80 8 ton electric forklift truck.

It will be “Humanity’s Biggest Eye”: a new gigantic optical telescope – the Extremely Large Telescope (ELT) – in the Atacama Desert, Chile. Its view into deep space requires the 798 hexagonal mirror segments of the 39-metre main mirror to be aligned with an accuracy of two nanometres (10-9 metre)! This is possible by using ZERODUR made by SCHOTT AG in Mainz. An 8-ton electric forklift truck specially obtained from STILL enables the glass melting tank to be handled. Optimum coordination between the drive system and precise hydraulic steering proved convincing: another RX 60-80 will be delivered in the near future.

SCHOTT mirrors provide sharp images from deep space

SCHOTT supplied the first large-dimension telescope mirror substrate in 1903. SCHOTT’s astronomical telescope mirrors have made a decisive contribution to exploration of the universe since that time. Telescopes must capture as much light as possible to allow an ever-deeper view into space. SCHOTT glass-ceramic mirror substrates enable sharp images. With its ten-year construction period, the ELT is the most spectacular project by the European Southern Observatory (ESO). First light is scheduled for 2024.

Every aspect must be perfect when melting the glass

SCHOTT has invested in new melting capacities and post-processing facilities at the Mainz Glass Ceramic Competence Centre. The new glass melting tank is designed for mirror substrates up to 4.25 metres in diameter. It will also be used to cast circular disks for the ELT’s primary mirror and the two ZERODUR mirror substrates for its secondary and tertiary mirrors. There is also a very large demand for ZERODUR glass ceramic for other applications, which is why SCHOTT is already investing in a second melting tank.

To manufacture glass ceramic with the required properties from the raw glass, it must be reheated. As the temperature rises during the ceramization process, added substances form tiny crystals that contract when heated and counteract the thermal expansion of the pure glass. Precise matching between the crystalline and vitreous phases can even achieve almost zero expansion for certain temperature ranges. This process can last up to several months. Thus casting and ceramizing each of the ELT’s mirror segments will require nearly four months. At peak periods, one circular disk will then be completed every day.

Tank handling with an 8-ton electric forklift truck

When handling the casting mould with molten liquid glass, the STILL RX 60-80 electric forklift truck gave a convincing performance due to its compact truck dimensions and precise hydraulic steering. With the least possible environmental impacts, this powerful electric forklift truck is extremely manoeuvrable and allows working aisle widths of less than five metres. The laterally offset cabin with a raised driving seat guarantees an unobstructed view of the castings, both through the lifting mast and past it at the side. Large viewing windows, a low-level tilt cylinder and the truck’s external contour enable a very good all-round view. This kind of overview considerably increases workplace safety and operational readiness, and leads to a lower risk of injury and damage. State-of-the-art proportional valve technology ensures sensitive operation and con- tinuously variable hydraulic control of the lifting speed. In addition, the truck’s low centre of gravity and steering axle with a high self-aligning bearing ensure optimum stationary stability. Its very good directional stability during tricky cornering with the very heavy casting mould is convincing. Moreover, speed, acceleration and braking behaviour are individually adjustable.

Conclusion

The ergonomically mature functional design of the STILL RX 60-80 electric forklift truck with its eight-ton load capacity convinced SCHOTT. Minimal environmental impact, compact construction, extreme manoeuvrability and accurate, sensitive steering when handling the casting mould together with safety during transport are the arguments in favour of further investment in a second truck.